Cov kab ntau lawm ntawm lub tais qe tsis siv neeg yog tsim los ntawm lub tshuab pulping, lub tshuab tsim, lub tshuab ziab, lub tshuab stacking, lub tshuab nqus tsev, lub tshuab dej siab thiab lub tshuab cua siab. Siv cov ntawv xov xwm pov tseg, cov ntawv thawv pov tseg, cov ntawv ua haujlwm hauv chaw ua haujlwm, cov khoom seem thiab lwm cov ntawv pov tseg ua cov khoom siv raw, los ntawm kev sib cais hydraulic, kev lim dej, kev txhaj dej thiab lwm yam txheej txheem los npaj qee qhov concentration ntawm slurry, los ntawm lub tshuab molding ntawm cov pwm hlau tshwj xeeb los ntawm kev nqus tsev nqus tsev Ib qho chaw ntub dej yog tsim, uas tom qab ntawd qhuav ntawm kab ziab, thiab tom qab ntawd stacked tom qab kub-nias on-line.

| Qauv | YB-1*3 | YB-1*4 | YB-3*4 | YB-4*4 | YB-4 * 8 | YB-5 * 8 | YB-6 * 8 |

| Peev Xwm (pcs/h) | 1000 | 1500 xyoo | 2500 | 3500 | 4500 | 5500 | 7000 |

| Tsim Cov Pwm Kom Muaj Peev Xwm | 3 | 4 | 12 | 16 | 32 | 40 | 48 |

| Tag Nrho Lub Hwj Chim (kw) | 40 | 40 | 50 | 60 | 130 | 140 | 186 |

| Kev Siv Hluav Taws Xob (kw/h) | 28 | 29 | 35 | 42 | 91 | 98 | 130 |

| Tus Neeg Ua Haujlwm | 3-5 | 4-6 | 4-6 | 4-6 | 4-6 | 5-7 | 6-8 |

1 * 3 tus neeg siv khoom lub vev xaib

1 * 4 txhua yam hauv ib lub tshuab kuaj tshuab

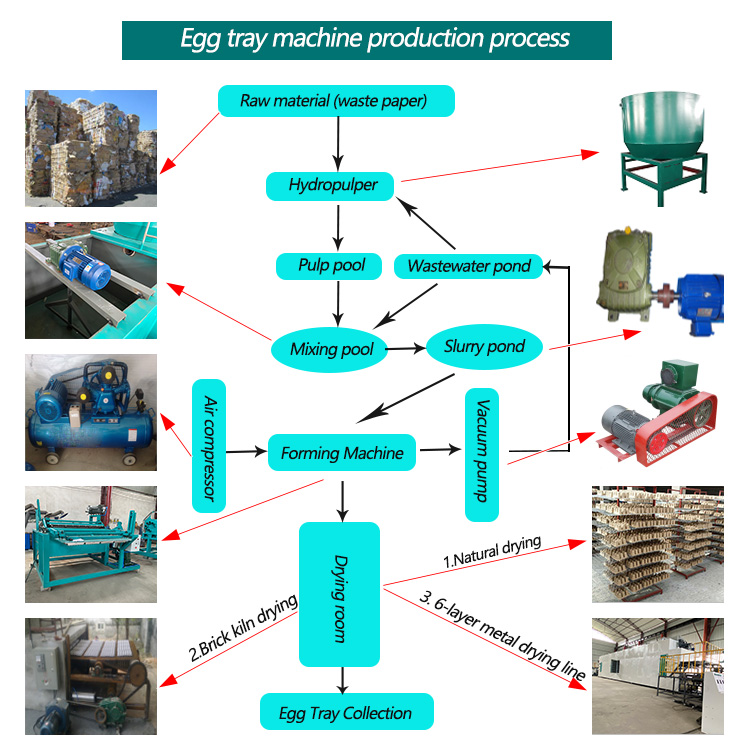

Cov txheej txheem ntau lawm:

1. Lub kaw lus pulping

Muab cov khoom siv raw rau hauv lub pulper thiab ntxiv cov dej kom tsim nyog rau lub sijhawm ntev kom do cov ntawv pov tseg rau hauv pulp thiab khaws cia rau hauv lub tank cia.

2. Kev tsim cov txheej txheem

Tom qab cov pwm raug adsorbed, cov pwm hloov pauv raug cua tshuab tawm los ntawm lub siab zoo ntawm lub tshuab cua compressor, thiab cov khoom pwm raug cua tshuab los ntawm lub pwm tuag mus rau lub pwm rotary, thiab raug xa tawm los ntawm cov pwm hloov pauv.

3. Lub tshuab ziab khaub ncaws

(1) Txoj kev ziab ntuj: Cov khoom raug ziab ncaj qha los ntawm huab cua thiab cua ntuj.

(2) Kev ziab ib txwm muaj: lub qhov cub cib, qhov chaw cua sov tuaj yeem xaiv cov roj av, diesel, thee, ntoo qhuav

(3) Kab ziab tshiab ntau txheej: kab ziab hlau 6 txheej tuaj yeem txuag tau ntau dua 30% zog

4. Cov khoom ntim khoom tiav lawm

(1) Lub tshuab stacking tsis siv neeg

(2) Lub tshuab ntim khoom

(3) Hloov cov khoom siv thauj khoom

1. Tus tswv tsev siv Taiwan gear divider technology los ua kom tiav qhov kev ua haujlwm ntawm cov khoom siv nrog 0 qhov yuam kev.

2. Lub hauv paus tshuab tseem ceeb ntawm lub tshuab qe tais txais yuav cov hlau 16 # channel uas tuab, thiab lub qav tsav yog precision machined nrog 45 # puag ncig hlau.

3. Cov kabmob tsav tsheb tseem ceeb yog ua los ntawm Harbin, Watt, thiab Luo bearings.

4. Tus tswv tsev qhov chaw swb yog welded nrog 45 # steel phaj tom qab kev kho cua sov.

5. Cov twj tso kua dej, cov twj tso kua dej, cov twj nqus tsev, cov tshuab cua, cov cav, thiab lwm yam yog ua los ntawm cov khoom lag luam zoo hauv tsev.

4 * 8 hlau ziab tshuab kuaj

6 * 8 qhov chaw ziab hlau

Ntau Cov Lus Qhia Ntxiv

Cov Lus Cim:

★. Tag nrho cov qauv khoom siv tuaj yeem hloov kho raws li qhov loj me raws li cov neeg siv khoom xav tau tiag tiag.

★. Tag nrho cov khoom siv yog welded nrog lub teb chaws tus qauv hlau.

★. Cov khoom siv kis tau tseem ceeb tuaj yeem tsav los ntawm cov kabmob NSK uas xa tuaj.

★. Lub cav tsav tsheb tseem ceeb reducer adopts heavy-duty high-precision reducer.

★. Lub positioning swb adopts sib sib zog nqus ua, tiv thaiv-hnav thiab zoo milling.

★. Tag nrho lub tshuab lub cev muaj zog yog txhua hom thawj kab hauv tebchaws, lav 100% tooj liab.

★. Cov kev ntsuas tiv thaiv tau siv rau cov khoom siv hluav taws xob, tshuab, cov kav dej, thiab lwm yam kom ntev lub neej kev pabcuam.

★. Muab cov neeg siv khoom nrog cov phiaj xwm tsim khoom siv kom ntxaws thiab siv cov duab kos dawb.

-

Cov Ntawv Pov Tseg Rov Siv Dua Lub Thawv Qe Qe Thawv Qe Thawv M...

-

Lub Tshuab Ua Qe Rau Cov Qe Uas Muaj Pulp Moulding Rau Cov Qe Me Me

-

Tsis siv neeg puv qe tais ua tshuab qe faib ...

-

Tsis siv neeg ntawv pulp qe tais ntau lawm kab /...

-

Xyoob Hluas Daim Ntawv Qe Ua Tshuab Ua Lub Tais Diav ...

-

1 * 4 pov tseg ntawv Pulp Moulding ziab qe tais tshuab