1.Pulp Moulding ntau lawm kab yog lub npe hu ua qe tais kab rau siv massively nyob rau hauv tsim qe tais.

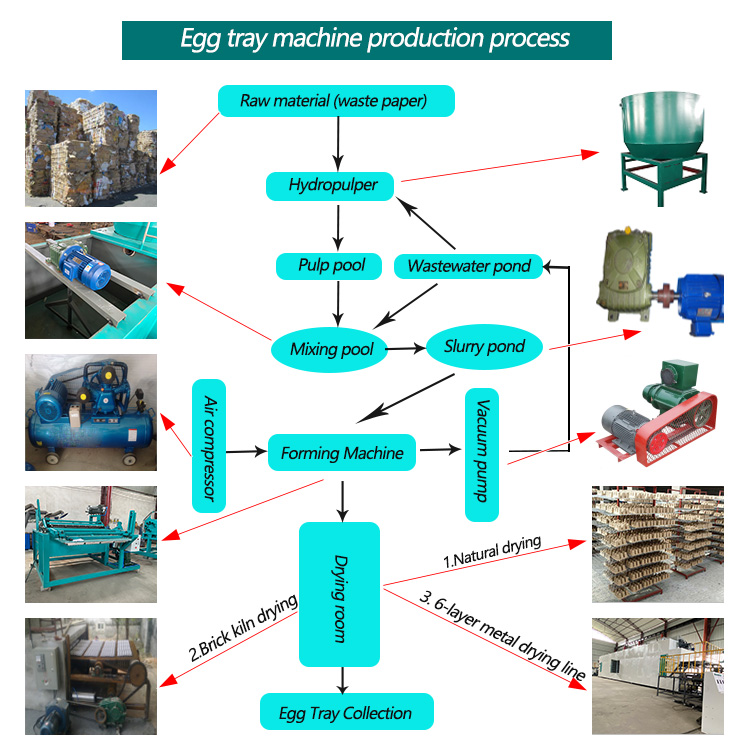

2.Pulp cov kab ke tsim khoom, uas siv cov ntawv pov tseg khib nyiab, thiab pulp no ua kom muaj cov khoom siv ntub, los ntawm kev ziab khaub ncaws tshwj xeeb, thiab ua kom qhuav, thiab shaping los ua cov khoom tiav.

3.Pulp Moulding Line processing ua rau kev siv cov dej rov ua dua tshiab thiab tsis ua rau dej los yog huab cua paug. Cov khoom ntim tiav tuaj yeem rov ua dua tom qab siv rau hauv kev khaws cia, thauj, thiab muag khoom. Tom qab shredding, lawv yog ib qho yooj yim rau decomposed li ntawv, txawm yog muab pov tseg rau hauv lub ntuj ib puag ncig.

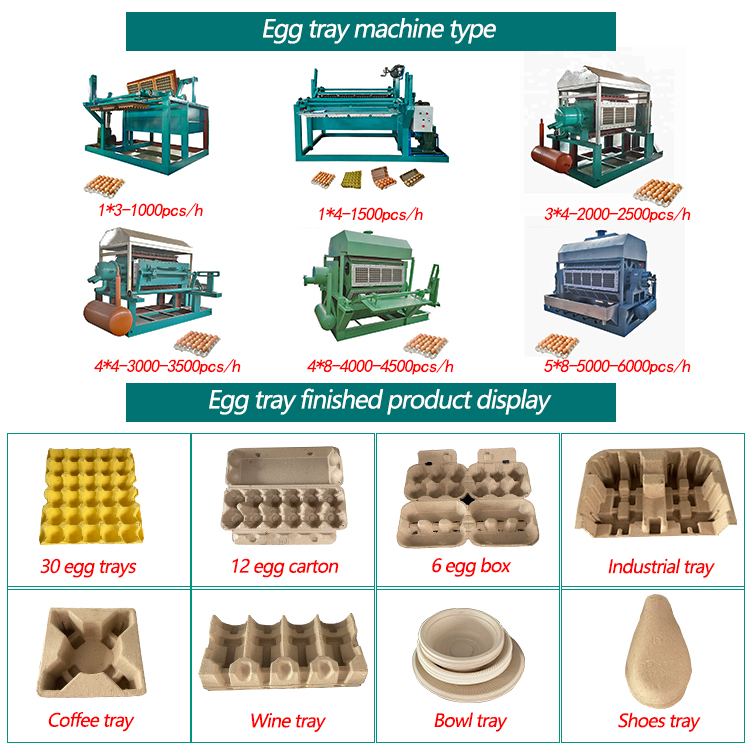

4.Automatic pulp molding ntau lawm kab tuaj yeem ua ntau ntau ntawm ntau lub thawv zaub mov, qe tais, lub thawv noj su thiab lwm yam.

| Tshuab Qauv | 1 * 3/1 * 4 | 3 * 4 * 4 | 4 * 8 / 5 * 8 | 5 * 12 / 6 * 8 |

| Tawm tswv yim (p / h) | 1000-1500 | 2500-3000 | 4000-6000 | 6000-7000 |

| Cov ntawv pov tseg (kg / h) | 80-120 : kuv | 160-240 : kuv | 320-400 Nws | 480-560 : kuv |

| Dej (kg / h) | 160-240 : kuv | 320-480 : kuv | 600-750 | 900-1050 Nws |

| Hluav taws xob (kw / h) | 36-37 : kuv | 58-78 : kuv | 80-85 : kuv | 90-100 ib |

| Rhiav cheeb tsam | 45-80 : kuv | 80-100 | 100-140 Nws | 180-250 : kuv |

| Qhov chaw qhuav | Tsis xav tau | 216 | 216-238 : kuv | 260-300 Nws |

High precision servo lub cev muaj zog tsav, ua haujlwm siab thiab txuag hluav taws xob kom qhuav kab.

1, Siv precision reducer servo lub cev muaj zog sib sau thiab xa mus kom ntseeg tau tias smith thiab ua haujlwm ceev.

2, Siv cov encoder kom ua tiav qhov kev kho kom raug.

3, Kev siv bronze casting static thiab dynamic nplhaib qauv yog tsim nyog rau cov khoom dewatering txheej txheem.

4, Kev siv cov qauv siv tshuab los xyuas kom meej tias cov pwm kaw ntawm ob sab sib npaug.

5, Muaj peev xwm loj; Cov ntsiab lus dej tsawg; Txuag tus nqi ntawm kev ziab.

1.Pulping system

2. txoj kev tsim

3. Tshuab ziab khaub ncaws

(3) Cov kab ntau txheej ziab qhuav: 6-txheej hlau ziab kab tuaj yeem txuag tau ntau dua 30% lub zog

4. Cov khoom tiav cov khoom pabcuam ntim

(2) Baler

(3) Hloov conveyor