Lub tshuab ua qe tais 3x4 tuaj yeem tsim tau 2,000 daim tais qe pulp ib teev, uas yog qhov tsim nyog rau tsev neeg me me lossis kev tsim khoom hauv chaw ua haujlwm. Vim nws cov khoom tsim tau me me, feem ntau cov neeg siv khoom siv lub hnub ci ncaj qha kom tau txais txiaj ntsig zoo dua. Siv lub khib ziab tes los hloov lub tais qe rau ntawm pwm, thiab tom qab ntawd siv lub laub thawb lub tais qe mus rau qhov chaw ziab kom ziab. Raws li huab cua, nws feem ntau yuav qhuav li ntawm 2 hnub.

Tom qab ziab lawm, nws raug sau los ntawm tes, ntim rau hauv hnab yas rau kev kho kom tsis txhob noo noo, ntim thiab khaws cia rau hauv lub tsev rau khoom. Cov khoom siv raw ntawm lub tais ntawv qe tais yog cov ntawv pov tseg phau ntawv, cov ntawv xov xwm pov tseg, cov thawv ntawv pov tseg, txhua yam ntawv pov tseg thiab cov ntawv seem los ntawm cov chaw luam ntawv thiab cov chaw ntim khoom, cov ntawv zeb twm pulp pov tseg, thiab lwm yam. Cov neeg ua haujlwm xav tau rau cov qauv khoom siv qe tais no yog 3-5 tus neeg: 1 tus neeg hauv thaj chaw ntaus, 1 tus neeg hauv thaj chaw tsim, thiab 1-3 tus neeg hauv thaj chaw ziab.

| Qauv Tshuab | 3 * 1 | 4 * 1 | 3 * 4 | 4 * 4 | 4 * 8 | 5 * 8 |

| Cov qoob loo (p / h) | 1000 | 1500 xyoo | 2000 xyoo | 2500 | 4000 | 5000 |

| Daim Ntawv Pov Tseg (kg / h) | 120 | 160 | 200 | 280 | 320 | 400 |

| Dej (kg / h) | 300 | 380 | 450 | 560 | 650 | 750 |

| Hluav taws xob (kw/h) | 32 | 45 | 58 | 78 | 80 | 85 |

| Thaj Chaw Ua Haujlwm | 45 | 80 | 80 | 100 | 100 | 140 |

| Thaj Chaw Ziab Khaub Ncaws | Tsis xav tau | 216 | 216 | 216 | 216 | 238 |

1. Lub tshuab pulping

(1) Muab cov khoom siv raw rau hauv lub tshuab pulping, ntxiv cov dej kom tsim nyog, thiab do ntev kom tig cov ntawv pov tseg mus ua pulp thiab khaws cia rau hauv lub tank cia pulp.

(2) Muab cov pulp tso rau hauv lub tank cia pulp rau hauv lub tank sib tov pulp, kho qhov concentration ntawm pulp hauv lub tank sib tov pulp, thiab ntxiv do cov dej dawb hauv lub tank rov qab thiab cov pulp concentrated hauv lub tank cia pulp los ntawm homogenizer. Tom qab kho kom haum rau cov pulp, nws raug muab tso rau hauv lub tank muab pulp rau siv hauv lub molding system.

Cov khoom siv siv: tshuab pulping, homogenizer, twj pulping, vibrating screen, tshuab pulping

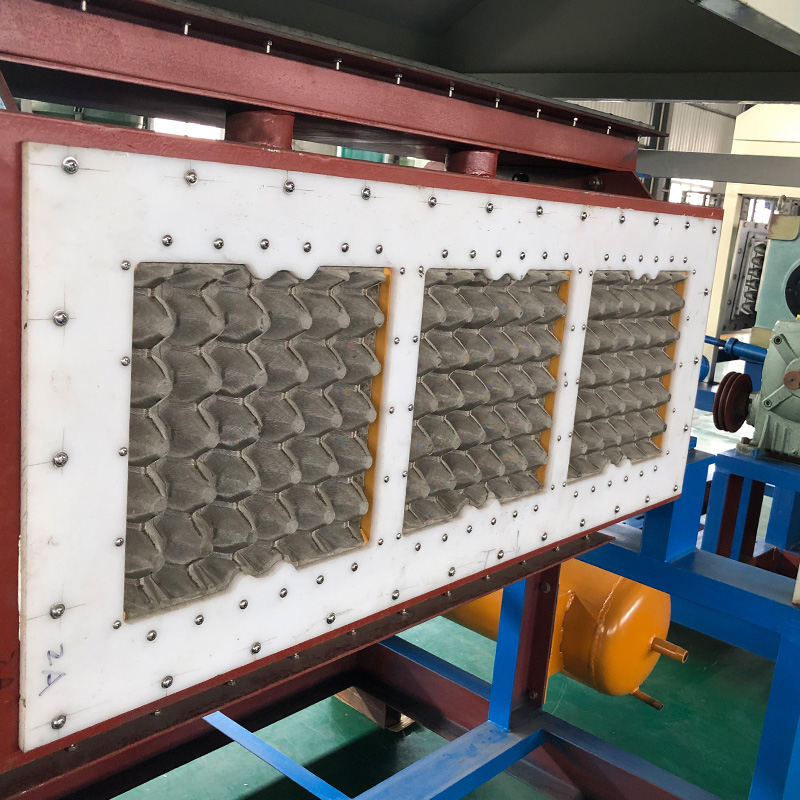

2. Lub kaw lus pwm

(1) Cov pulp hauv lub tank pulp supply raug xa mus rau hauv lub tshuab ua, thiab cov pulp raug adsorbed los ntawm lub tshuab nqus tsev. Cov pulp raug dhau los ntawm lub pwm ntawm cov khoom siv kom tawm cov pulp ntawm lub pwm kom tsim, thiab cov dej dawb raug adsorbed los ntawm lub twj tso kua mis thiab tsav rov qab mus rau hauv pas dej.

(2) Tom qab cov pwm raug adsorbed, cov pwm hloov pauv raug nias tawm los ntawm lub tshuab cua compressor, thiab cov khoom pwm raug tshuab los ntawm cov pwm tsim mus rau cov pwm hloov pauv, thiab cov pwm hloov pauv raug xa tawm.

Cov khoom siv siv: tshuab ua pwm, pwm, twj tso kua mis nqus tsev, lub tank siab tsis zoo, twj tso kua mis dej, cua compressor, tshuab ntxuav pwm

3. Lub tshuab ziab khaub ncaws

(1) Txoj kev ziab ntuj: Cia siab rau huab cua thiab cua ntuj kom ziab cov khoom.

(2) Kev ziab ib txwm muaj: lub qhov cub cib, qhov chaw cua sov tuaj yeem xaiv los ntawm cov roj av, diesel, thee, thiab ntoo qhuav. Cov chaw cua sov xws li cov roj av liquefied.

(3) Kab ziab ntau txheej: Kab ziab hlau 6-txheej tuaj yeem txuag tau ntau dua 20% zog dua li qhov ziab kis, thiab qhov chaw cua sov tseem ceeb yog roj av, diesel, roj av liquefied, methanol thiab lwm yam khoom siv hluav taws xob huv.

-

Cov Ntawv Pov Tseg Rov Siv Dua Lub Thawv Qe Qe Thawv Qe Thawv M...

-

YB-1 * 3 lub tshuab ua qe tais 1000pcs / teev rau lub bu ...

-

1 * 4 pov tseg ntawv Pulp Moulding ziab qe tais tshuab

-

Tsis siv neeg ntawv pulp qe tais ntau lawm kab /...

-

Tsis siv neeg puv qe tais ua tshuab qe faib ...

-

Tshuab ua qe tais ntawv pov tseg tsis siv neeg ...