Muab ib qho lus hais dawb rau peb hnub no!

Lub hauv paus ntsiab lus ua haujlwm yog rov dov thiab tho cov ntawv loj raws li qhov xav tau. Lub tshuab siv cov hlau sib txuas rau cov kab dotted stamping, nrog rau qhov zoo ntawm kev hnav tsawg, suab nrov tsawg thiab cov qauv embossed sib txawv. Qhov nruj thiab qhov loj ntawm daim ntawv thiab qhov hnyav tuaj yeem hloov kho tau.

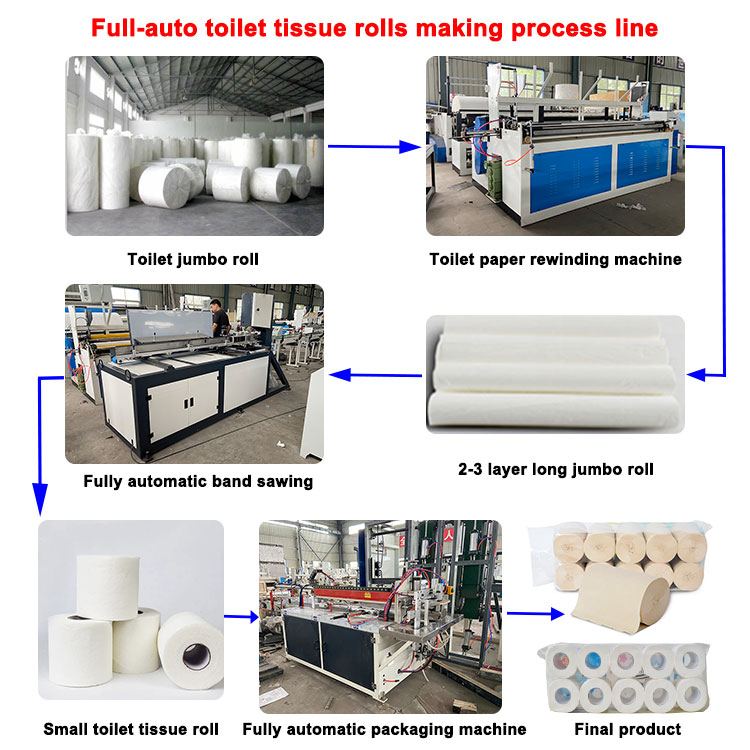

Txoj Cai Ua Haujlwm

Plaub-roller tsis siv neeg pub mis → synchronous conveying → embossing → punching → tsis siv neeg winding → txiav → packing → sealing.

1. Rewinding --- Lub hom phiaj tseem ceeb ntawm lub tshuab rewinding ntawv yog ua cov ntawv loj loj rau hauv ib daim ntawv ntev ntawm cov ntawv yob.

2. Txiav daim ntawv --- Daim ntawv ntev ntawm chav dej txiav los ntawm lub tshuab txiav ntawv raug txiav ua cov khoom tiav ib nrab ntawm qhov ntev

raws li tus neeg siv khoom xav tau.

3. Ntim Khoom --- Cov khoom ntim tuaj yeem ntim rau hauv lub tshuab ntim khoom lossis qhwv tes, thiab cov khoom tiav ib nrab ntawm cov ntawv so quav tau ntim thiab kaw los ntawm lub tshuab sib khi.

| Qauv Tshuab | YB-1575/1880/2400/2800/3000 |

| Qhov Hnyav Ntawv Raw | 12-40 g/m2 daim ntawv so quav jumbo yob |

| Tiav lawm txoj kab uas hla | 50mm-200mm |

| Cov Ntawv Ua Tiav Lawm | Txoj kab uas hla 30-55 hli (Thov Qhia meej) |

| Tag Nrho Lub Hwj Chim | 4.5kw-10 kw |

| Kev Ceev Ntau Lawm | 150-300m/feeb |

| Hluav taws xob | 220/380V, 50HZ |

| Sawv Tom Qab | Peb txheej sib kis sib txuas |

| Perforation Pitch | 80-220mm, 150-300mm |

| Ntaus | 2-4 Riam, Kab Txiav Kauv |

| Qhov Pitch | Kev Tso Chaw ntawm Siv thiab Log Saw |

| Kev Tswj Xyuas | PLC Tswj, Kev Tswj Ceev Zaus Hloov Pauv, Kev Ua Haujlwm Kov Screen |

| Kev luam tawm | Ib qho Embossing, Ob Chav Embossing |

| Tso Raj | Tes, Tsis Siv Neeg (Xaiv Tau) |

1. Lub tshuab no yog rau kev ua cov ntawv so quav, tag nrho cov qauv yog phab ntsa-hom, uas ua rau lub tshuab khiav ruaj khov ntawm kev kub ceev, thiab tsis muaj suab nrov.

2. Qhov nrug ntawm qhov perforation yog kho tau kom tau raws li qhov xav tau sib txawv.

3. Lub tshuab pub mis tsis siv neeg, thawb lub cav tom qab rov qab, tom qab ntawd rov qab qhib lub cav tshiab dua.

4. Tsis siv neeg ntug-trimming, kua nplaum txau thiab sealing synchronously hauv ib lub sijhawm. Tawm 10-18 hli tail, yooj yim rau rewind dua, yog li txo cov shortcut pov tseg thiab txuag tus nqi.

5. Txais yuav thoob ntiaj teb advanced PLC programmable tswj cov txheej txheem, txiv neej-tshuab interface ua haujlwm, cov ntaub ntawv teeb tsa thiab parametric txhaum qhia om kov screen.

6. Txais yuav 4 daim siab Precision kauv riam, suab qis, perforation meej, txais yuav gearbox kom muaj ntau yam loj dua.

7. Ob lub phab ntsa hom nraub qaum, lub tshuab nqa pneumatic, nrog rau txoj siv dav dav; txhua lub yob jumbo tuaj yeem hloov kho tau ywj pheej.

8. Txais cov jogging keyboards rau hnav daim ntawv, yooj yim thiab muaj kev nyab xeeb rau kev khiav lag luam.

Koj puas npaj txhij los nrhiav paub ntxiv?

-

YB-2L cov tswv yim lag luam me me ntawv so ntsej muag ...

-

Tshuab Ua Ntawv So Tes Semi-Automatic

-

1/8 quav OEM 2 xim tsis siv neeg daim ntaub so ntswg fo ...

-

OEM Kev Cai Siab Zoo Nruab Nrab Ceev Tsis Siv Neeg ...

-

Lub tswv yim ua lag luam me me ntawm daim ntawv so tes ntawm lub rooj ...

-

YB-1575 tshuab ua ntawv so quav tsis siv neeg ...