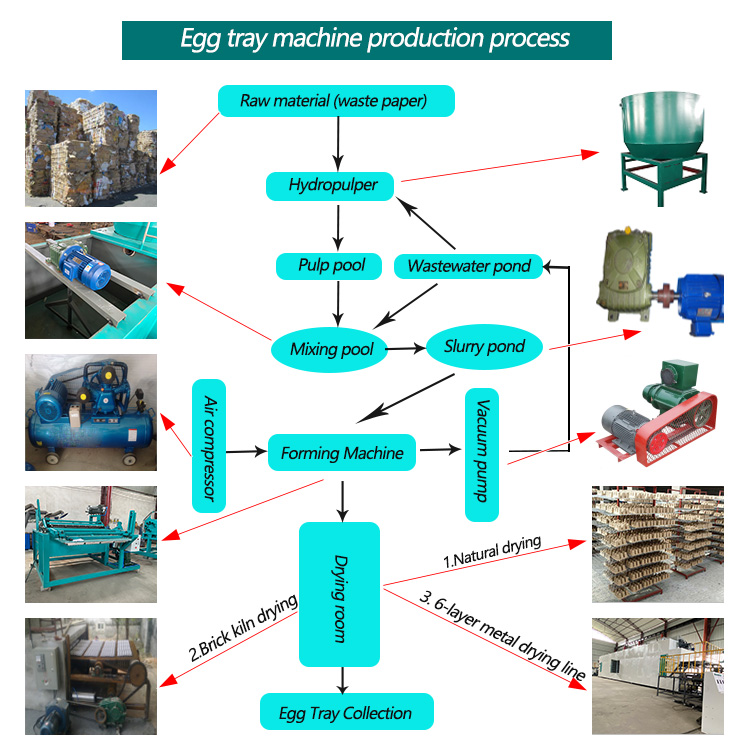

Cov kab ntau lawm ntawm Young Bamboo pulp molding tsis siv neeg lub tais qe feem ntau siv cov ntawv pov tseg ua cov khoom siv raw, uas muaj cov khoom nplua nuj thiab tus nqi qis, thiab yog kev txhim kho thiab siv cov khib nyiab. Cov dej siv hauv cov txheej txheem tsim khoom raug kaw thiab rov ua dua tshiab, tsis muaj dej khib nyiab lossis cov pa khib nyiab raug tso tawm. Tom qab siv cov khoom siv pwm pwm, cov khib nyiab tuaj yeem rov ua dua tshiab zoo li ntawv ib txwm muaj. Txawm tias nws raug tso tseg rau hauv ib puag ncig ntuj, nws yooj yim lwj thiab lwj mus rau hauv ntawv ib txwm muaj. Cov khoom organic yog cov khoom zoo rau ib puag ncig. Cov ntawv pov tseg raug ntxiv rau hauv lub tshuab pulper thiab dej raug xa mus rau lub tank cia. Cov pulp hauv lub tank cia raug xa mus rau lub tank muab khoom nrog lub tshuab sib tov. Cov pulp hauv lub tank muab khoom raug do rau qee qhov concentration thiab xa mus rau lub tshuab molding. Lub tshuab molding tsim lub tais qe rau txoj siv Conveyor. Txoj siv conveyor hla dhau txoj kab ziab kom qhuav lub tais qe, thiab thaum kawg nws raug sau thiab ntim. Tsis tas li ntawd, lub twj tso kua mis tuaj yeem twj cov dej tsis siv hauv lub tshuab molding mus rau lub tank backwater. Lub tank backwater tuaj yeem thauj dej mus rau lub tshuab pulper thiab lub tank cia pulp, thiab cov dej tuaj yeem rov ua dua tshiab.

Cov ntaub ntawv raw feem ntau yog los ntawm ntau yam pulp boards xws li reed pulp, straw pulp, slurry, xyoob pulp thiab ntoo pulp, thiab pov tseg ntawv, pov tseg ntawv thawv ntawv, pov tseg ntawv dawb, ntawv zeb twm pulp pov tseg, thiab lwm yam. Pov tseg ntawv, tau dav thiab yooj yim rau kev sau. Tus neeg teb xov tooj xav tau yog 5 tus neeg / chav kawm: 1 tus neeg hauv thaj chaw pulping, 1 tus neeg hauv thaj chaw molding, 2 tus neeg hauv lub laub, thiab 1 tus neeg hauv pob khoom.

| Qauv Tshuab | 1 * 3 | 1 * 4 | 3 * 4 | 4 * 4 | 4 * 8 | 5 * 8 | 5 * 12 | 6 * 8 |

| Cov qoob loo (p / h) | 1000 | 1500 xyoo | 2500 | 3000 | 4000-4500 | 5000-6000 | 6000-6500 | 7000 |

| Daim Ntawv Pov Tseg (kg / h) | 80 | 120 | 160 | 240 | 320 | 400 | 480 | 560 |

| Dej (kg / h) | 160 | 240 | 320 | 480 | 600 | 750 | 900 | 1050 |

| Hluav taws xob (kw/h) | 36 | 37 | 58 | 78 | 80 | 85 | 90 | 100 |

| Thaj Chaw Ua Haujlwm | 45 | 80 | 80 | 100 | 100 | 140 | 180 | 250 |

| Thaj Chaw Ziab Khaub Ncaws | Tsis xav tau | 216 | 216 | 216 | 216 | 238 | 260 | 300 |

2. Lub zog txhais tau tias yog cov khoom tseem ceeb, tsis suav nrog cov kab ziab khaub ncaws

3. Tag nrho cov roj siv feem pua yog xam los ntawm 60%

4. ib lub tshuab ziab khaub ncaws ntev 42-45 'meter', ob txheej 22-25 'meter', ntau txheej tuaj yeem txuag tau thaj chaw ua haujlwm

-

YB-1 * 3 lub tshuab ua qe tais 1000pcs / teev rau lub bu ...

-

Tsis siv neeg ntawv pulp qe tais ntau lawm kab /...

-

Xyoob Hluas Daim Ntawv Qe Ua Tshuab Ua Lub Tais Diav ...

-

Tshuab ua qe tais ntawv pov tseg tsis siv neeg ...

-

1 * 4 pov tseg ntawv Pulp Moulding ziab qe tais tshuab

-

Lub Tshuab Ua Qe Rau Cov Qe Uas Muaj Pulp Moulding Rau Cov Qe Me Me