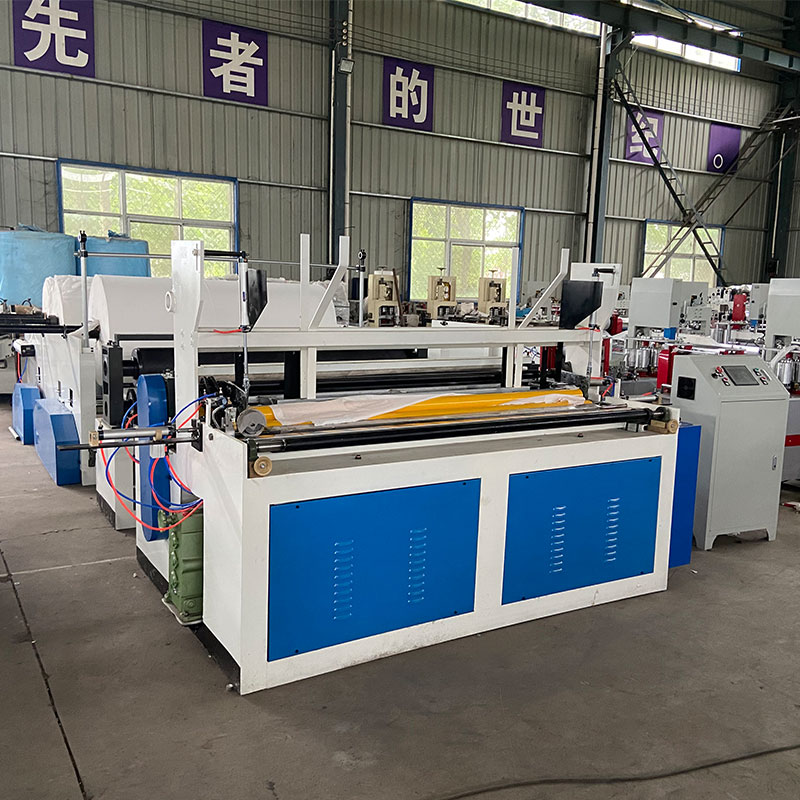

Lub tshuab rewinding ntawv so quav tuaj yeem rewind lub jumbo quav yob mus rau hauv me me yob nrog ntau yam me me raws li qhov xav tau. nws tsis hloov qhov dav ntawm jumbo yob, ces, lub me me txoj kab uas hla yob tuaj yeem txiav mus rau hauv ntau qhov loj me me ntawm cov ntawv so quav yob. Nws feem ntau yog siv nrog lub tshuab txiav band pom thiab lub tshuab ntim thiab kaw ntawv yob.

Lub tshuab no siv lub tshuab PLC computer programming tshiab thoob ntiaj teb (lub kaw lus tuaj yeem hloov kho dua tshiab), kev tswj zaus, lub tshuab hluav taws xob tsis siv neeg. Lub kaw lus ua haujlwm kov-hom tib neeg-tshuab interface siv lub tshuab rewind tsis muaj coreless. daim ntawv thov PLC program cua kem tsim thev naus laus zis ua tiav cov yam ntxwv ntawm kev rewinding sai dua thiab molding zoo nkauj dua.

| Lub npe khoom | Tshuab Rewinding Ntawv Tsis Siv Neeg |

| Qauv tshuab | YB-1575/1880/2100/2400/2800/3000/S3000 |

| Lub hauv paus ntawv yob txoj kab uas hla | 1200 hli (Thov qhia meej) |

| Jumbo yob lub plawv txoj kab uas hla | 76 hli (Thov qhia meej) |

| Ntaus | 2-4 riam, kab txiav kauv |

| Kev tswj hwm lub cev | PLC tswj, kev tswj ceev zaus hloov pauv, kev ua haujlwm kov npo |

| Cov khoom ntau yam | ntawv tseem ceeb, ntawv tsis tseem ceeb |

| Tso lub raj xa dej | phau ntawv thiab tsis siv neeg (xaiv tau) |

| Ua haujlwm ceev | 80-280 m/feeb |

| Lub zog | 220V/380V 50HZ |

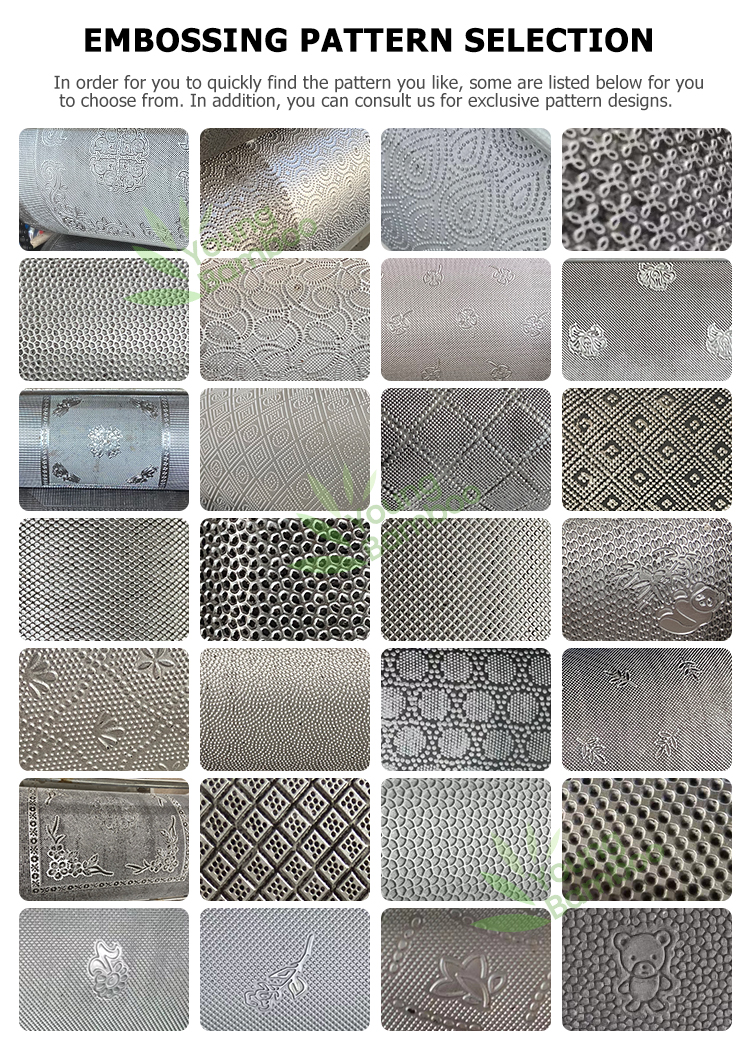

| Kev luam tawm | Ib qho embossing, ob chav embossing |

| Kev tso tawm khoom tiav lawm | Tsis siv neeg |

Daim ntawv so quav Lub tog raj kheej liner embossing; embossing roller

Cov kab ntau lawm ntawm cov ntawv so quav semi-automatic rewinding tshuab muaj peb ntu

Ua ntej 【siv lub tshuab rewinding ntawv chav dej los rewind lub yob ntawv loj mus rau hauv ib lub yob ntawv me me ntawm lub hom phiaj txoj kab uas hla】

Tom qab ntawd 【siv tes sawing los txiav cov yob ua ib daim ntawv me me ntawm lub hom phiaj ntev Yob】

Thaum kawg, 【siv lub tshuab sealing dej txias lossis lwm lub tshuab ntim khoom los kaw lub yob ntawv】

Piv rau cov kab ntau lawm ntawv so quav semi-automatic

Qhov zoo ntawm cov kab ntau lawm ntawv so quav tsis siv neeg yog kom nce kev tsim khoom thiab txuag zog

Ua ntej 【siv lub tshuab rewinding ntawv chav dej los rewind lub yob ntawv loj mus rau hauv ib lub yob ntawv me me ntawm lub hom phiaj txoj kab uas hla】

Tom qab ntawd 【 daim ntawv me me tom qab rewinding yuav dhau los ntawm lub tshuab txiav ntawv chav dej tsis siv neeg thiab txiav ua ib daim ntawv me me ntawm qhov ntev uas xav tau. 】

Thaum kawg, 【cov ntawv me me tom qab txiav yuav dhau los ntawm txoj siv conveyor thiab raug thauj mus rau lub tshuab ntim ntawv chav dej tsis siv neeg rau kev ntim khoom. Ntau yam ntawv yob tuaj yeem ntim tau raws li qhov xav tau.】

1. Siv PLC lub khoos phis tawj los sau cov ntawv tiav hauv cov txheej txheem rov ua kom tiav qhov nruj thiab xoob ntawm qhov sib txawv nruj kom daws qhov xoob ntawm cov khoom tiav vim yog kev khaws cia ntev.

2. Lub tshuab rewinding puv nkaus tuaj yeem xaiv ob sab embossing, gluing compound, uas tuaj yeem ua rau daim ntawv mos dua li ib sab embossing, cov nyhuv ntawm ob sab tiav lawm yog sib xws, thiab txhua txheej ntawm daim ntawv tsis kis thaum siv, tshwj xeeb tshaj yog haum rau kev ua tiav.

3. Lub tshuab muaj nruab nrog kev ua cov ntawv so quav uas tsis xav tau, khov kho, uas tuaj yeem hloov pauv ntawm cov khoom tam sim ntawd, thiab kuj tuaj yeem xaiv raws li tus neeg siv xav tau.

4. Kev txiav tsis siv neeg, txau kua nplaum, kaw, thiab ntxig daim ntawv ua tiav ua ke, yog li ntawd tsis muaj kev poob ntawv thaum txiav daim ntawv yob rau hauv lub tshuab txiav thiab ntim, uas ua rau kev tsim khoom zoo dua thiab qib ntawm cov khoom tiav. Yooj yim rau siv.

5. Siv txoj siv pneumatic pub mis, ob chav reel thiab txhua txoj kab ntawm daim ntawv thawj muaj kev hloov kho qhov nro ywj pheej

-

Tshuab ntim ntawv so quav tag nrho tsis siv neeg ...

-

YB-2400 Cov lag luam me me tsis siv neeg lub tshuab ua ntawv so quav ...

-

YB-1 * 3 lub tshuab ua qe tais 1000pcs / teev rau lub bu ...

-

Phau ntawv band pom ntawv txiav tshuab rau semi ...

-

Tag nrho automatic jumbo yob slitting tshuab maxi ...

-

YB-4 txoj kab phuam mos mos ua ntawv so ntsej muag ...