Kev Kub Ceev Tag Nrho Tsis Siv Neeg Ua tiav Kab Ntau Lawm Me Me Chav Dej Da Dej Ntaub So Tes Ua Tshuab Nqe Hauv Suav Teb

Lub tshuab no tuaj yeem rov ua dua daim ntawv so quav loj loj rau ntau txoj kab uas hla me me yam tsis hloov nws qhov dav. Txoj kab uas hla thiab qhov nruj ntawm cov ntawv so quav tiav lawm tuaj yeem hloov kho tau yooj yim los ntawm kev hloov qhov chaw ntawm lub vaj huam sib luag tswj, thiab cov ntawv tso zis tawm tau npaj rau kev txiav.

Lub tshuab rho ntawv so quav no siv AC zaus hloov pauv stepless ceev kev tswj hwm, uas tuaj yeem khiav ruaj khov thaum cov neeg siv khoom hloov nws qhov ceev.

Lub tshuab no muaj PLC system thiab Human Machine Interface control panel kom ib tus neeg siv tau yooj yim heev. Nws yog lub tshuab zoo tagnrho rau lub Hoobkas ua ntawv so quav me me.

| Qauv | YB-1880 | YB-3000 |

| Jumbo yob dav (hli) | ≦2200 hli | ≦3000 hli |

| Qhov loj ntawm daim ntawv nyoos | 76.2 hli | |

| Txoj kab uas hla ntawm cov khoom tiav lawm | 90-250 hli (Lwm Qhov Loj Yuav Tsum Tau Qhia) | |

| Qhov loj ntawm cov khoom tiav lawm | Φ 32-50 hli | |

| Qhov Deb Ntawm Perforation | 100-150 hli (Lwm Qhov Loj Yuav Tsum Tau Qhia) | |

| Kev txiav thiab kaw lub Tail | txiav tag nrho, tus tw kaw zoo nkauj thiab ruaj khov; Lub tank cia khoom kom tuav cov kua nplaum | |

| Kev tsav tsheb tseem ceeb | Kev tswj hwm zaus hloov pauv zaus 7.5-15KW 380V, 50HZ | |

| Lub cev tub ntxhais: | Tsis siv neeg lub hauv paus thauj khoom | |

| Qhov tob ntawm perforation | 6 Cov Hniav, 110mm | |

| Kev teeb tsa parameter | HMI | |

| Tshuab ceev | 0-300m/feeb | |

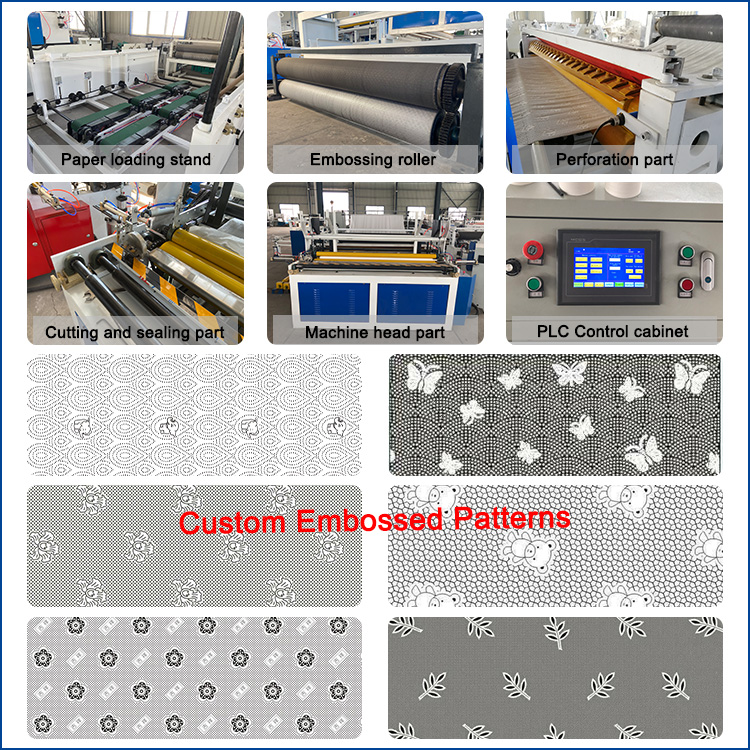

| Chav Embossing | Hlau rau roj hmab / hlau rau hlau / hlau rau ntaub plaub embossing | |

| Cua-system | 3HP cua compressor, min. siab 5kg/cm2pa (muab los ntawm tus neeg siv) | |

| Kev tsav tsheb kho tshuab | Tsav tsheb los ntawm lub thawv iav tsis muaj kauj ruam | |

| Qhov hnyav | 3T | 4T |

| Chav Lamination | Yuav Tsum Tau Txiav Txim | |

Plaub-roller tsis siv neeg pub mis → synchronous conveying → embossing → punching → tsis siv neeg winding → txiav → packing → sealing.

1. Rewinding --- Lub hom phiaj tseem ceeb ntawm lub tshuab rewinding ntawv yog ua cov ntawv loj loj rau hauv ib daim ntawv ntev ntawm cov ntawv yob.

2. Txiav daim ntawv --- Daim ntawv ntev ntawm chav dej txiav los ntawm lub tshuab txiav ntawv raug txiav ua cov khoom tiav ib nrab ntawm qhov ntev

raws li tus neeg siv khoom xav tau.

3. Ntim Khoom --- Cov khoom ntim tuaj yeem ntim rau hauv lub tshuab ntim khoom lossis qhwv tes, thiab cov khoom tiav ib nrab ntawm cov ntawv so quav tau ntim thiab kaw los ntawm lub tshuab sib khi.

1. Siv PLC lub khoos phis tawj los sau cov ntawv tiav hauv cov txheej txheem rov ua kom tiav qhov nruj thiab xoob ntawm qhov sib txawv nruj kom daws qhov xoob ntawm cov khoom tiav vim yog kev khaws cia ntev.

2. Lub tshuab rewinding puv nkaus tuaj yeem xaiv ob sab embossing, gluing compound, uas tuaj yeem ua rau daim ntawv mos dua li ib sab embossing, cov nyhuv ntawm ob sab tiav lawm yog sib xws, thiab txhua txheej ntawm daim ntawv tsis kis thaum siv, tshwj xeeb tshaj yog haum rau kev ua tiav.

3. Lub tshuab muaj nruab nrog kev ua cov ntawv so quav uas tsis xav tau, khov kho, uas tuaj yeem hloov pauv ntawm cov khoom tam sim ntawd, thiab kuj tuaj yeem xaiv raws li tus neeg siv xav tau.

4. Kev txiav tsis siv neeg, txau kua nplaum, kaw, thiab ntxig daim ntawv ua tiav ua ke, yog li ntawd tsis muaj kev poob ntawv thaum txiav daim ntawv yob rau hauv lub tshuab txiav thiab ntim, uas ua rau kev tsim khoom zoo dua thiab qib ntawm cov khoom tiav. Yooj yim rau siv.

5. Siv txoj siv pneumatic pub mis, ob chav reel thiab txhua txoj kab ntawm daim ntawv thawj muaj kev hloov kho qhov nro ywj pheej

-

1/4 quav daim ntaub so ntswg ua tshuab

-

Xyoob Hluas Daim Ntawv Qe Ua Tshuab Ua Lub Tais Diav ...

-

Tshuab txiav band sawing automatic rau kev siv tshuab...

-

Kev tsim khoom me me tsis siv neeg ntawv pov tseg ...

-

Tsis Siv Neeg Kauv Daim Ntawv Core Ua Tshuab Yeeb Nkab

-

Tshuab Ua Ntawv Soj Ntsuam Ua tiav Cov Khoom Siv...